Mat.No. 1.1121, DIN Ck10, AISI 1010

Short Description:

Designation by Standards Mat. No. DIN EN AISI 1.1121 Ck10 - 1010 Chemical Composition (in weight %) C Si Mn Cr Mo Ni V W Others 0.10 max. 0.40 0.45 - - - - - - Description CK10 is a plain carbon steel with a nominal 0.10% carbon content. It is a relatively low strength steel but it may be quenched and tempered for increased strength. Applications The low carbon steels, such as CK10, are used for applications such as cold headed fasteners and ...

Product Detail

FAQ

Product Tags

Designation by Standards

| Mat. No. | DIN | EN | AISI |

| 1.1121 | Ck10 | - | 1010 |

Chemical Composition (in weight %)

| C | Si | Mn | Cr | Mo | Ni | V | W | Others |

| 0.10 | max. 0.40 | 0.45 | - | - | - | - | - | - |

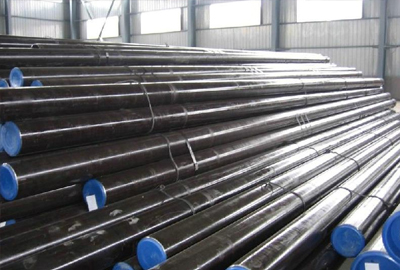

Description CK10 is a plain carbon steel with a nominal 0.10% carbon content. It is a relatively low strength steel but it may be quenched and tempered for increased strength. Applications The low carbon steels, such as CK10, are used for applications such as cold headed fasteners and bolts. Physical properties (avarage values) at ambient temperature Modulus of elasticity [103 x N/mm2]: 210 Density [g/cm3]: 7.85 Soft Annealing Heat to 800-840oC, cool slowly. Hardening This steel is generally used in the annealed or case hardened condition. It may be heat treated, quenched and tempered but the cost for so doing is generally not worth the result. Tempering Tempering temperature: 320-530oC. Forging Hot forming temperature: 1050-850oC. Machinability Machinability of CK10 steel is fairly good, especially in the cold drawn or cold worked condition. Based upon carbon steel AISI 1112 as a reference that is considered 100% machinable (easily machined) the CK10 steel has a rating of 55%. Corrosion Resistance This is a plain carbon steel and has no corrosion resistance. It will rust unless protected. Welding CK10 steel may be welded by all of the standard welding techniques. Cold working CK10 is easily cold worked by traditional means. Following severe cold working a stress relief, or full, anneal should be performed. Disclaimer The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other puposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

FAQ Content

![[0{7)7UAZ(]4W{5TSMC65Q7](https://www.htsteelmill.com/uploads/077UAZ4W5TSMC65Q7.png)