DIN 1.2842 / AISI O2 Tool Steel for Punches

Equivalence

|

AISI / SAE

|

DIN / W.Nr

|

JIS

|

GB

|

|

O2

|

1.2842

|

—-

|

9Mn2V+Cr

|

Chemical Composition (%)

|

Steel Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

V

|

|

1.2842

|

0.85

0.95

|

0.10

0.40

|

1.80

2.20

|

≤

0.030

|

≤

0.030

|

0.20

0.50

|

—-

|

0.05

0.15

|

|

O2

|

0.85

0.95

|

≤

0.50

|

1.40

1.80

|

≤

0.030

|

≤

0.030

|

≤

0.50

|

≤

0.30

|

≤

0.30

|

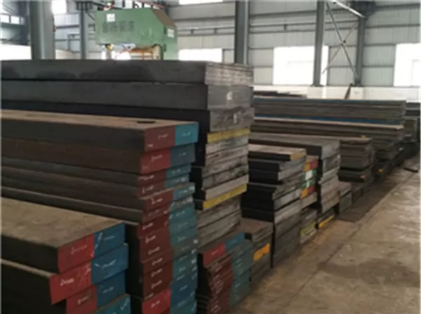

Dimensions

|

Shape

|

Thick / Dia. (mm)

|

Width (mm)

|

|

Round

|

8-700

|

/

|

|

Flat

|

1.6-200

|

20-1000

|

|

Block

|

150-600

|

200-1500

|

Delivery Condition

EAF+LF+VD, Hot rolled or Forged, Spheroidizing Annealed, Hardness≤220HB, Unmachined or Machined surface (Peeled, Turned, Milled, Grinded), UT 100% Passed

Characteristics

1. Cold work tool steel with high dimensional stability at heat treatment.

2. Very high cracking resistance. High machinability, medium thoughness and wear resistance.

Applications

Tools (punches) and dies for blanking, punching and similar operations; threading and wood working tools, machine knives for the pulp, paper and metal working industries; measuring tools and plastic mould dies.

Heat Treatment

Annealing

680 to 720°C

Slow controlled cooling in furnace at a rate of 10 to 20°C/hr down to approx. 600°C, further cooling in air. Hardness af ter annealing: Max. 220 HB.

Stress relieving

Approx. 650°C

Slow cooling in furnace; intended to relieve stresses set up by extensive machining, or in complex shapes. After through heating, hold in neutral atmosphere for 1-2 hours.

Hardening

790 to 820°C

Oil, salt bath (200 to 250°C) up to 20 mm thickness. Holding time after temperature equalization: 15 to 30 minutes. Obtainable hardness: 63 – 65 HRC

Tempering

Slow heating to tempering temperature immediately after hardening/time in furnace 1 hour for each 20 mm of work piece thickness, but at least 2 hours/cooling in air.For certain cases we recommend to reduce tempering temperature and increase holdingtime.

Previous: ASME SA537 Class 1 Steel Plates

Next: 4145H steel

![[0{7)7UAZ(]4W{5TSMC65Q7](https://www.htsteelmill.com/uploads/077UAZ4W5TSMC65Q7.png)