DC53,Cr8Mo1VSi Alloy steel

Short Description:

1. Chemical composition standard grade C Si Mn Cr P S Mo V GB Cr8Mo1VSi 0.90-1.05 0.80-1.10 0.2-0.5 7.50-8.40 ≤0.03 ≤0.015 1.80-2.10 0.15-0.35 JIS DC53 0.90-1.10 0.80-1.20 ≤0.40 7.50-8.50 ≤0.03 ≤0.03 1.80-2.20 0.20-0.50 2.Applications • red planted mold , cold mold, cold drawing dies • roll forming punch • precision stamping die . • line cutting , precision blanking dies and stamping dies for various purposes . • difficult to machine materials, plastic deformation tools . • fo...

Product Detail

FAQ

Product Tags

1. Chemical composition

| standard | grade | C | Si | Mn | Cr | P | S | Mo | V |

| GB | Cr8Mo1VSi | 0.90-1.05 | 0.80-1.10 | 0.2-0.5 | 7.50-8.40 | ≤0.03 | ≤0.015 | 1.80-2.10 | 0.15-0.35 |

| JIS | DC53 | 0.90-1.10 | 0.80-1.20 | ≤0.40 | 7.50-8.50 | ≤0.03 | ≤0.03 | 1.80-2.20 | 0.20-0.50 |

2.Applications

• red planted mold , cold mold, cold drawing dies

• roll forming punch

• precision stamping die .

• line cutting , precision blanking dies and stamping dies for various purposes .

• difficult to machine materials, plastic deformation tools .

• forging, deep drawing and Roll with the mold .

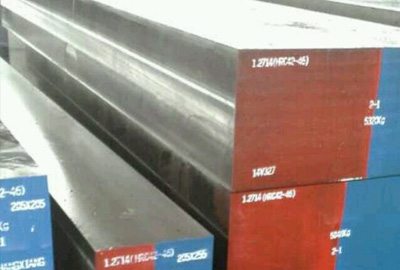

3.Specifications

|

Material

|

Alloy Tool Steel round or plate Bar DC53,Cr8Mo1VSi | Round bar | Dia(mm) | 18mm-220mm | ||||

| Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | 2000mm-6000mmm | |||||

| Heat treatment | Annealed / Quenched / tempered | Plate bar | Thickness | 20mm-400mm | ||||

| Delivery condition | grinded,black,machined | Width(mm) | 60mm-600mm | |||||

| Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | 2000mm-6000mmm | |||||

4. Other details

| Process | EAF+LF+VD+(ESR)+Forging+(Rolling)+Annealing Condition (optional) | ||

| Delivery Condition | grinded,black,machined | ||

| Technical Data | According to customer’s requirements | ||

| Ultrasonic Test | Ultrasonic test according to SEP 1921-84 G3 D/d E/d | ||

FAQ Content

![[0{7)7UAZ(]4W{5TSMC65Q7](https://www.htsteelmill.com/uploads/077UAZ4W5TSMC65Q7.png)